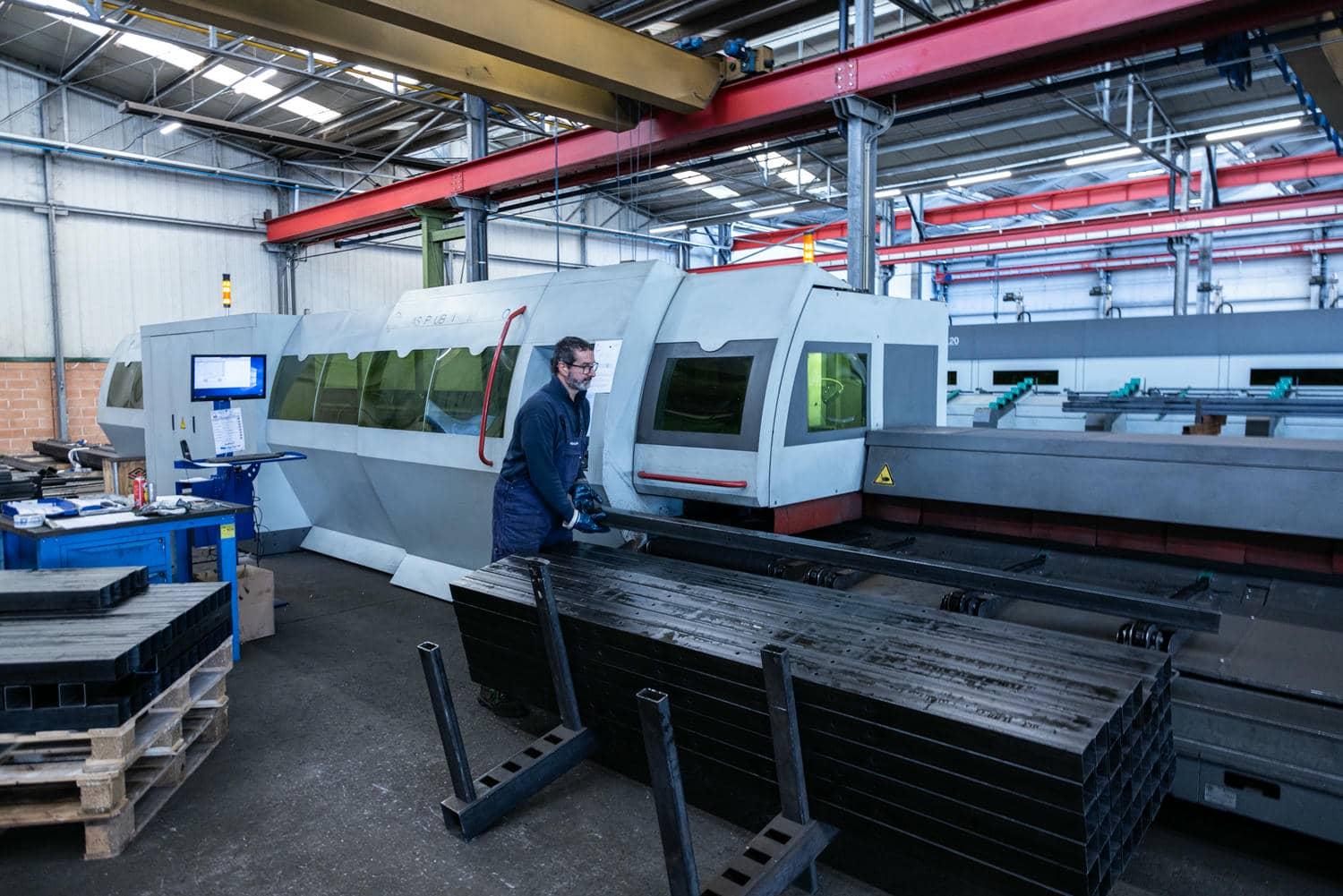

Tube cutting

Request a quoteElletielle's tube laser cutting service provides you with the products you need for your orders with precision and speed. Starting from a consultation with our sales or technical department, we work together to assess the required tube laser cutting for your order.

You will be supported by one of our managers, who will evaluate your needs, check the feasibility of the tube cutting, and address any requirements you have for the order, all the way through to the delivery of your materials.

Work machine

Lasertube LT FIBER EVO

Round tube (mm)

min. 12 - max. 152,4

Square tube (mm)

min. 12 x 12 mm - max. 120 x 120

Rectangular tube (mm)

min. 10 x 12 mm - max. 140 x 100

Open profiles

Angolari - L - UNP

Bar weight (kg/m)

max. 15

Workable materials

mild steel, stainless steel, aluminum, copper, brass

Beam load length (mm)

6495

Discharge length (mm)

6495

Work machine

LT JUMBO 20

Max spessore taglio

20 mm

Taglio inclinato possibile

max 45° <= 20 mm

Tubo tondo

Ø min 80 mm - max 508 mm

Tubo quadro

min 80 x 80 mm - max 400 x 400 mm

Tubo rettangolare

min 120 x 80 mm - max 500 x 300 mm

Travi lavorabili

IPE da 120 a 500

HEA da 160 a 400

HEB da 160 a 400

Massimo peso barra da lavorare

200 Kg/m

Lunghezza barra caricabile

min 4000 mm - max 18000 mm

Scarico pezzi corti

fino a 3000 mm

Scarico pezzi lunghi

min 3000 mm - max 18000 mm

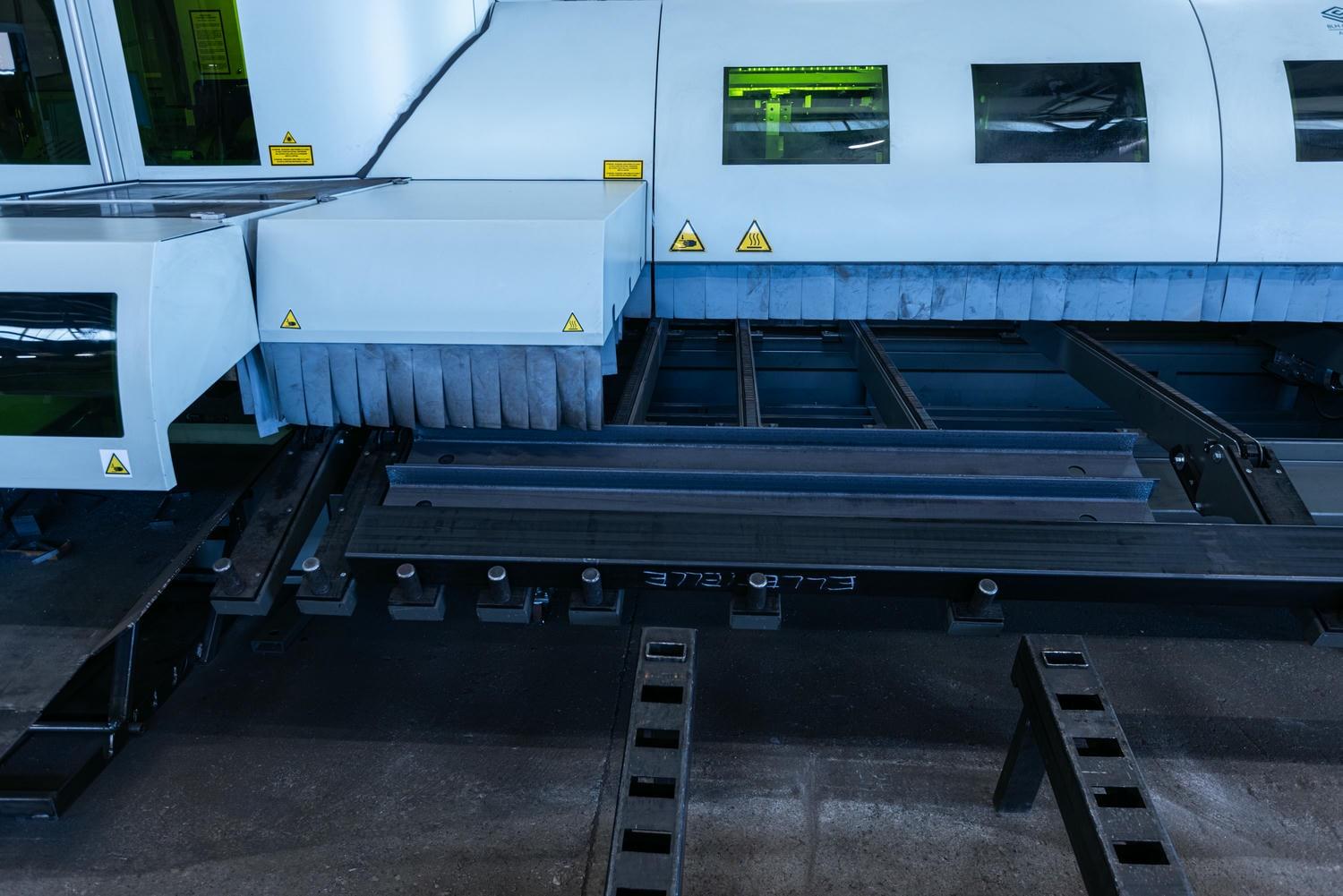

Work machine

LT 8.20

Questo macchinario è altamente specializzato per il taglio di tubi e profilati metallici. Il sistema impiega la tecnologia del laser per garantire precisione e alta qualità nei tagli, con un'ampia capacità di lavorazione su diverse tipologie di materiali. Il modello LT8.20 è progettato per offrire una gestione efficiente e rapida dei tubi, con un'area di lavoro che consente il taglio di tubi di diverse dimensioni e lunghezze. È dotato di un controllo numerico avanzato, che ottimizza il processo e riduce gli sprechi. L'uso del laser permette di ottenere tagli complessi, precisi e senza necessità di post-lavorazioni. Esso è equipaggiato con due caricatori principali, progettati per ottimizzare il flusso di lavoro e la produttività.

Caricatore passo-passo: progettato per caricare tubi di diverse sezioni, ottimizzando la movimentazione e garantendo una gestione versatile dei materiali. Questo sistema permette di caricare i tubi uno alla volta, adattandosi facilmente a sezioni variabili.

Caricatore a fascio: consente il carico di interi fascicoli di tubi con la stessa sezione, riducendo i tempi di carico e aumentando l'efficienza del processo. Questo sistema è ideale per gestire grandi volumi di tubi con dimensioni uniformi, migliorando la produttività complessiva del sistema.

L. Max carico: 12500 mm

L. Max scarico: 8500 mm

Kg/m max: 40 kg/m

Sez. Lavorate: Ø ◘ ∟H profili speciali